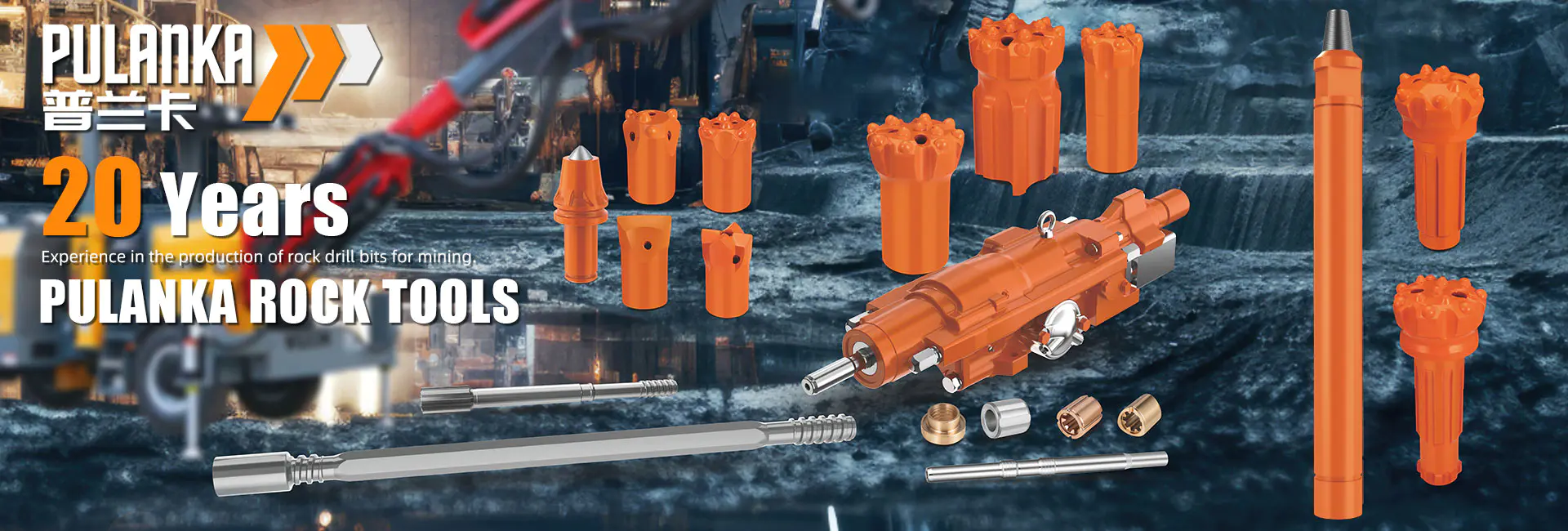

WHY CHOOSE PULANKA

SUSTAINABILITY, SERVICE & SATISFACTION

Research & Development

Since its inception, research and development (R&D) has served as the fundamental pillar for the survival and expansion of Pulanka Rock Tools. Leveraging the existing R&D laboratory infrastructure, Pulanka established an additional laboratory in 2023 to bolster technical capabilities and data resources, providing enhanced support for our clientele and internal team.

Investment for the future

With more than $15 million USD invested infactories and machining, Pulanka Rock Tools has total of 16 production lines with autonmous capabilities, as well as employing a workforce +300 skilled laborers.Our facilities span 430,000square feet, where we complete every step of assembly. We are complete every step of assembly.We are committed to investments that allow our customers to meet their markets supply and demand.

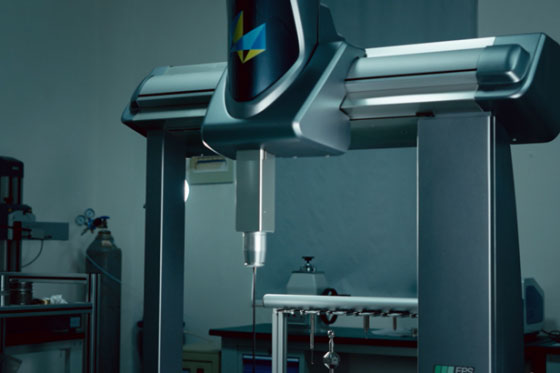

Quality & Inspection

Our company follows strict international quality system standards during the production process, This begins with a detailed analysis of the raw materials we receive and continues through an additional 58 steps of inspection before products leave our facility

Service Team

Customer satisfaction is our priority.Our sales team is equippedto handle multilingual interactions with customers and provideclear,effective communication.We want our partners and end-users to get maximum value from every product.Fieldrepresentatives are available to make site visits,when needed,tostudy and collect product information.We fully guarantee ourproducts against defects in material or workmanship.

Quarries

More mining application:

1. Surface mining

2. Underground soft rock mining

3. Underground hard rock mining

4. Production drilling of blastholes in quarries and mines.

Well Drilling

There are two main purposes for well drilling:

1. Waterwells

2. Geothermal wells

The required depth and size of the wells varies geographically due to pump standards and geology.

Tunneling

There are a number of sub applications within Tunneling which are

1. Pre-split ho

2. Buffer holes

3. Enviromental survey holes

4. Blast holes

Products Category

We specialize in production and development for many drilling applications; mining, quarry, well-drilling, tunneling, roadwork and other engineering applications. We have made consistent advancements in pursuit of providing customers with high-performance, sustainable and cost-effective rock tools.

Top Hammer Drilling

Top Hammer Drilling is a widely used technique in rock drilling, known for its efficiency and versatility. This method relies on a hammer mechanism positioned at the top of the drill string to deliver rapid, high-frequency impacts. These forces are transferred through the drill rods to the bit, which breaks the rock while rotating to ensure smooth and effective cutting. It’s commonly applied in industries such as construction, mining, quarrying, and tunneling and a ideal for tasks like blast hole drilling, rock bolting, and ground stabilization. Its modular design offers adaptability, making it suitable for a range of drilling environments, whether on the surface or underground. This flexibility has made it a popular choice for professionals in the field.

Down The Hole Drilling

Down-the-Hole (DTH) Drilling is a percussive drilling method used primarily in mining, quarrying, and construction for drilling hard rock formations. It is known for its efficiency and accuracy in creating deep, straight holes.

Down The Hole drilling: Hammer is at the bottom (near the bit), reducing energy loss (better for deep holes).

Jack Hammer Drilling

Jack hammer drilling is widely used in mining, tunnel excavation, and construction. Optimizing the transmission of impact and rotational force through taper design to improve drilling efficiency. Under different rock conditions, our tapered drilling tools exhibit good adaptability, can significantly reduce energy loss. Besides, cutting picks are widely used in coal and mineral mining, infrastructure construction, and other fields. Our cutting picks have outstanding wear resistance and impact resistance, which can improve the efficiency of coal and rock crushing and operation, shorten the construction period, and reduce production costs. Overall, tapered drilling tools are an ideal choice for modern engineering operations due to their excellent performance in facilitating efficient and high-quality drilling operations.