PRODUCTION PROCESS FLOW CHART

Pulanka pays attention to every detail so that it can obtain the eye-catching vision of the people. Pulanka brand is only one choice for each customer, but is thoroughly tempered by the company.

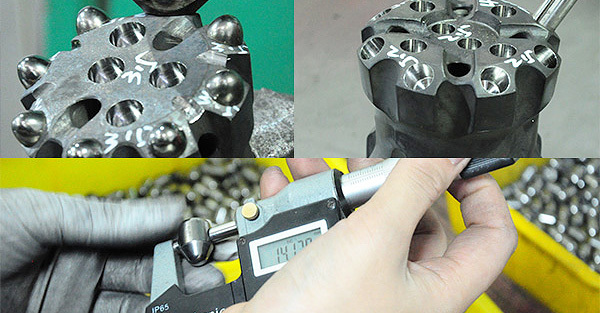

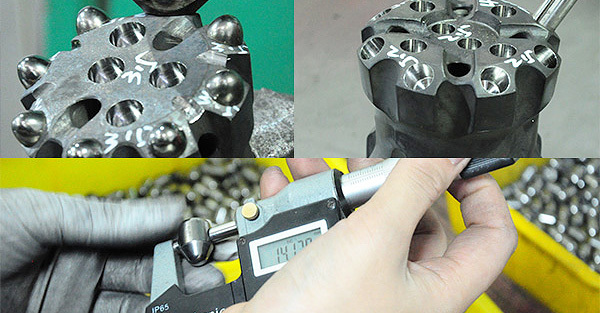

Step2-Machining

The drill bit body is machined for measurement specifications, flushing holes and sideslots for cutting removal.

Step 4-Carbide Pressing

Quality carbide is selected with strong support from a well-known and mature domestic supply chain to ensure the hardness and driling performance of our products is higherthan industry standards. During pressing, we measure every hole and button one-by-one to reduce the chance of performance issues.

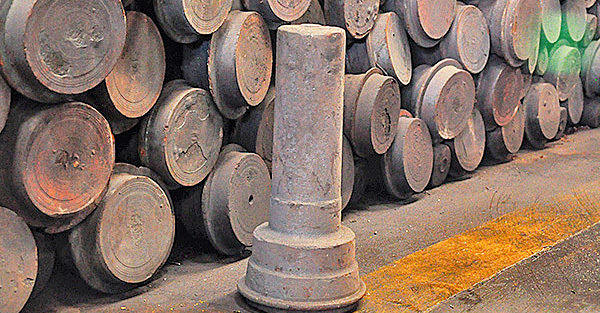

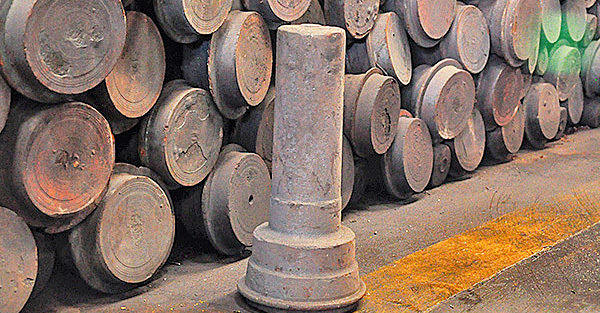

Step1-Forging

Quality steel is precision-forged to form the body of the drill bit.

Step3-Heat Treatment

Bits are placed inside our onsite, state-of-the-art heat treatment furnaces. We verifythat the steel remains within 1 degree of hardness, so the bit body maintains the highestlevel of strength and durability.

Step 5-Packing

Product is packaged for safe and convenient handling during shipments, insidewarehouses and on work sites.

01. FORGED

Special steel is precision-forged to form a drill housing.

02. PROCESSING

Housing after high-efficiency and precision processing center equipment, the completion of powder drain, water hole structure integrated processing, in the machining to ensure the stability of product structure.

03. HEAT TREATMENT

Adopting internationally famous heat treatment equipment, steel element crystal processing upgrade, to ensure that the steel hardness remains in the range of 1 degree, so that the housing has high strength, but also has a high toughness.

04. ALLOY MATCHING

Alloys use well-known domestic enterprises to support, to ensure that in rock drilling operations, the comprehensive wear resistance of products higher than industry standards. When the housing and alloy combine, we use one hole, one tooth test, to ensure that the product in use, do not appear teeth, shedding phenomenon.

05. PACKAGING

Product packaging, we take high-end convenient packaging, for workers in the handling and use of convenient.