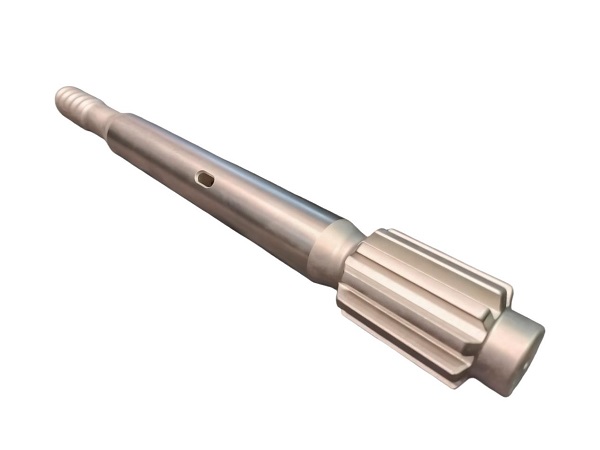

Nickel-plated shank adapter

2025-11-10

Technology-driven, Durable Innovation - Pulanka Unvews New Nickel-plated shank adapter , Redefining Rock Drilling Efficiency and Economic Benefits

Pulanka, a leading enterprise in the domestic rock drilling tool field, announced today that after years of dedicated research and development and rigorous testing, it has officially launched its revolutionary product - the new nickel-plated shank adapter to the market. The launch of this new product marks a major breakthrough for Pulanka in materials science and surface treatment technology, aiming to thoroughly address the core pain points faced by traditional drill tails in high-intensity rock drilling operations, such as wear, corrosion and short service life.

In heavy rock drilling operations such as mining and tunnel excavation, shank adapter, as a key component connecting the rock drill and the drill rod, its performance directly determines the efficiency and cost of the entire rock drilling system. Traditional drill tails generally have problems such as insufficient surface hardness, poor corrosion resistance, and high friction coefficient with the rock drill piston sleeve, which leads to a short service life and frequent replacement. This not only increases the downtime of the equipment and the cost of spare parts, but also affects the overall operation progress due to the decline in power transmission efficiency.

Pulanka new shank adapter addresses these issues head-on with its proprietary nickel-plating technology.Key Features and Technical Advantages:

Superior Wear Resistance: The advanced electroplating process creates an exceptionally hard, dense, and uniform nickel coating. This significantly enhances surface durability against the high-frequency impact of the piston and the rotational friction within the drill sleeve, extending service life by up to [e.g., 50% or more] compared to standard adapters.

Reduced Friction Coefficient: The nickel-plated surface exhibits self-lubricating properties, drastically lowering the coefficient of friction. This ensures more efficient transfer of impact energy from the rock drill to the bit, resulting in higher penetration rates and reduced energy consumption for the drilling equipment.

Excellent Corrosion Resistance: The impermeable nickel layer acts as a powerful barrier against water, moisture, and corrosive agents present in mine and tunnel environments. This prevents rust and pitting, guaranteeing consistent performance and reliability even in wet drilling conditions.

Enhanced Fatigue Strength: The coating helps to inhibit the initiation and propagation of micro-cracks, improving the adapter's resistance to impact fatigue and reducing the risk of premature failure, thereby boosting safety and operational reliability.

Related News