What Makes Thread Coupling Sleeves the Key Connector ?

2025-10-14

In the world of mechanical and industrial pipe connections, thread coupling sleeves play a crucial yet often overlooked role. They serve as the connecting joint between two threaded pipe ends, ensuring a secure, leak-free, and reliable connection that can withstand pressure, temperature, and vibration. Whether in construction, oil and gas pipelines, irrigation systems, or heavy machinery, the integrity of these connectors determines the performance and safety of the entire system.

A Thread Coupling Sleeve, also known as a threaded sleeve or pipe coupling, is typically made from high-grade carbon steel, stainless steel, or alloy steel. Its primary purpose is to join two male-threaded ends of pipes or rods. Depending on the material and application, these sleeves can be used for mechanical reinforcement, electrical grounding, or structural alignment.

The growing demand for durable and precision-engineered fittings in industrial infrastructure has made the Thread Coupling Sleeve an indispensable component. It’s not just a connector—it’s a performance enhancer that helps maintain structural stability and operational efficiency.

Below is a summary of key product parameters for a high-quality Thread Coupling Sleeve used across multiple industries:

| Parameter | Specification Range | Description |

|---|---|---|

| Material Options | Carbon Steel / Stainless Steel / Alloy Steel / Brass | Selected based on corrosion resistance and tensile strength requirements |

| Thread Standards | BSP / NPT / ISO / Metric | Ensures compatibility with regional and industrial thread types |

| Diameter Range | ½” to 8” (custom sizes available) | Supports a wide range of pipe and rod diameters |

| Surface Treatment | Zinc Plated / Black Oxide / Galvanized / Plain Finish | Enhances corrosion resistance and aesthetic appearance |

| Working Pressure | Up to 10,000 psi (depending on material and design) | Designed for both low- and high-pressure environments |

| Temperature Range | -50°C to +400°C | Suitable for extreme industrial operating conditions |

| Connection Type | Female-Female Thread | Allows easy joining of two male-threaded components |

| Certifications | ISO 9001 / CE / API Standards | Guarantees quality, safety, and compliance |

These parameters reflect the precision and consistency that define modern coupling sleeve manufacturing.

Why Are Thread Coupling Sleeves Critical for Industrial Applications?

The importance of thread coupling sleeves extends far beyond simple connection—it’s about ensuring efficiency, safety, and durability. In many industries, a small connector can make the difference between optimal performance and catastrophic failure. Here’s why they are so critical:

a. Structural Integrity and Pressure Resistance

A well-engineered thread coupling sleeve ensures that the joined sections can handle internal pressures without deformation or leakage. In high-pressure pipelines such as oil, gas, or hydraulic systems, the sleeve acts as a mechanical safeguard, preventing disconnection under stress.

b. Corrosion and Environmental Resistance

With advancements in metallurgy and coating technology, modern sleeves can resist harsh chemicals, moisture, and salt exposure. Stainless steel variants are particularly valuable in marine and chemical processing applications where corrosion is a major threat.

c. Easy Installation and Maintenance

Unlike welded joints, threaded sleeves allow for quick installation and easy disassembly. This simplifies maintenance, inspection, and replacement processes, reducing downtime and labor costs significantly.

d. Enhanced Load-Bearing Capacity

Thread coupling sleeves distribute tension evenly across connected parts, minimizing the risk of localized stress points. This makes them ideal for reinforcing rebar connections in construction or joining structural steel components.

e. Cost Efficiency Over the Product Lifecycle

Due to their reusable and non-welded nature, these sleeves save both time and cost in assembly lines and field operations. They reduce energy consumption (no welding required) and minimize material waste, aligning with sustainable industrial practices.

In today’s push for energy-efficient and sustainable engineering solutions, thread coupling sleeves contribute by promoting modularity, reusability, and lower carbon footprints—factors increasingly valued in global manufacturing.

How Are Thread Coupling Sleeves Evolving with Future Technology Trends?

The global market for coupling components is rapidly changing, influenced by automation, materials innovation, and environmental concerns. The Thread Coupling Sleeve industry is no exception. As industries modernize, the following trends are shaping its future:

a. Smart Manufacturing and Precision Engineering

Advanced CNC machining and digital thread profiling ensure every sleeve meets tight tolerance standards. Automated quality inspection reduces human error, ensuring perfect thread alignment and internal surface finish.

b. Integration of Composite Materials

While traditional steel remains dominant, composite and hybrid materials are emerging for lightweight, corrosion-proof applications. These are especially relevant in aerospace, offshore, and renewable energy systems where weight reduction is crucial.

c. Eco-Friendly Coating Technologies

Next-generation surface coatings like trivalent chromate and eco-zinc layers replace hazardous heavy-metal coatings, extending sleeve life while reducing environmental impact.

d. Modular and Customizable Designs

Manufacturers now provide modular thread coupling sleeves that can be customized in length, threading pattern, and coating finish. This flexibility meets diverse industry needs—from power generation to food processing systems.

e. Predictive Maintenance and IoT Monitoring

Emerging IoT-enabled fittings can monitor vibration, torque, and internal pressure, predicting wear before failure. While still in experimental stages, this development will redefine reliability in mechanical systems.

These innovations indicate that thread coupling sleeves are not static components; they are evolving toward greater intelligence, sustainability, and performance reliability. The industries adopting these trends will benefit from enhanced system integrity and longer equipment life cycles.

Common Questions About Thread Coupling Sleeves (FAQ Section)

Q1: What is the difference between a thread coupling sleeve and a union?

A1: While both are connectors, a thread coupling sleeve is used to join two threaded male ends directly, typically in a permanent or semi-permanent setup. A union, on the other hand, allows easy separation without disturbing the connected piping system, often incorporating an additional nut and sealing element.

Q2: How to select the right thread coupling sleeve for a specific application?

A2: Selection depends on several factors: the thread type (BSP, NPT, or Metric), working pressure, material compatibility, temperature range, and environmental exposure. For example, carbon steel sleeves are ideal for high-pressure hydraulic systems, while stainless steel versions are preferred in corrosive or sanitary environments. Always ensure the sleeve complies with ISO or API standards for safety and performance.

Q3: Can thread coupling sleeves be reused after disassembly?

A3: Yes, if the threads remain intact and free from damage. However, it is critical to inspect for wear, corrosion, or thread deformation before reuse. Applying thread sealant or Teflon tape during reinstallation helps maintain a secure and leak-free joint.

Q4: Are there international standards that regulate the quality of thread coupling sleeves?

A4: Yes. Common standards include ISO 9001 for quality management, API 5L/5CT for pipeline and tubing components, and ASTM A105 for carbon steel forgings. Compliance ensures consistent quality, dimensional accuracy, and mechanical performance across global supply chains.

The Future of Reliable Connections – Pulanka’s Commitment

The evolution of Thread Coupling Sleeves reflects a broader transformation in industrial connection technologies—from simple metal joints to engineered components optimized for strength, precision, and sustainability. With the rise of smart manufacturing and eco-conscious design, companies that prioritize innovation in coupling systems will lead the next industrial wave.

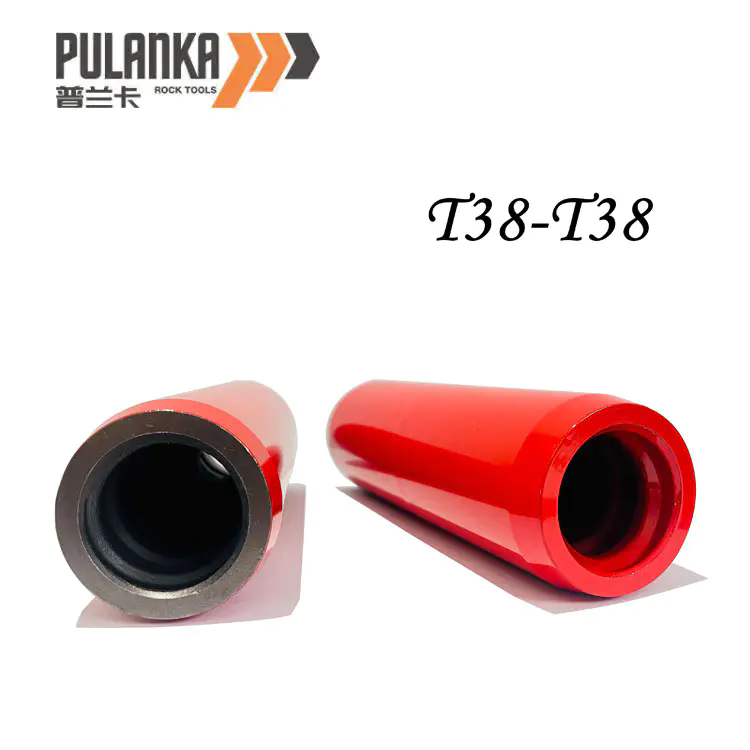

Pulanka has been at the forefront of this transformation. With a commitment to high-precision engineering, durable materials, and global quality standards, Pulanka’s thread coupling sleeves deliver unmatched reliability across industries. Each product undergoes rigorous testing to ensure superior tensile performance, leak resistance, and thread accuracy.

By integrating modern machining processes and sustainable coating technologies, Pulanka continues to redefine what industrial connectivity means in the 21st century. From heavy-duty oil and gas pipelines to precision-driven mechanical systems, Pulanka’s solutions guarantee strength where it matters most.

For tailored advice, product specifications, or bulk supply inquiries, contact us today to discover how Pulanka can support your next project with trusted and innovative connection solutions.

Related News