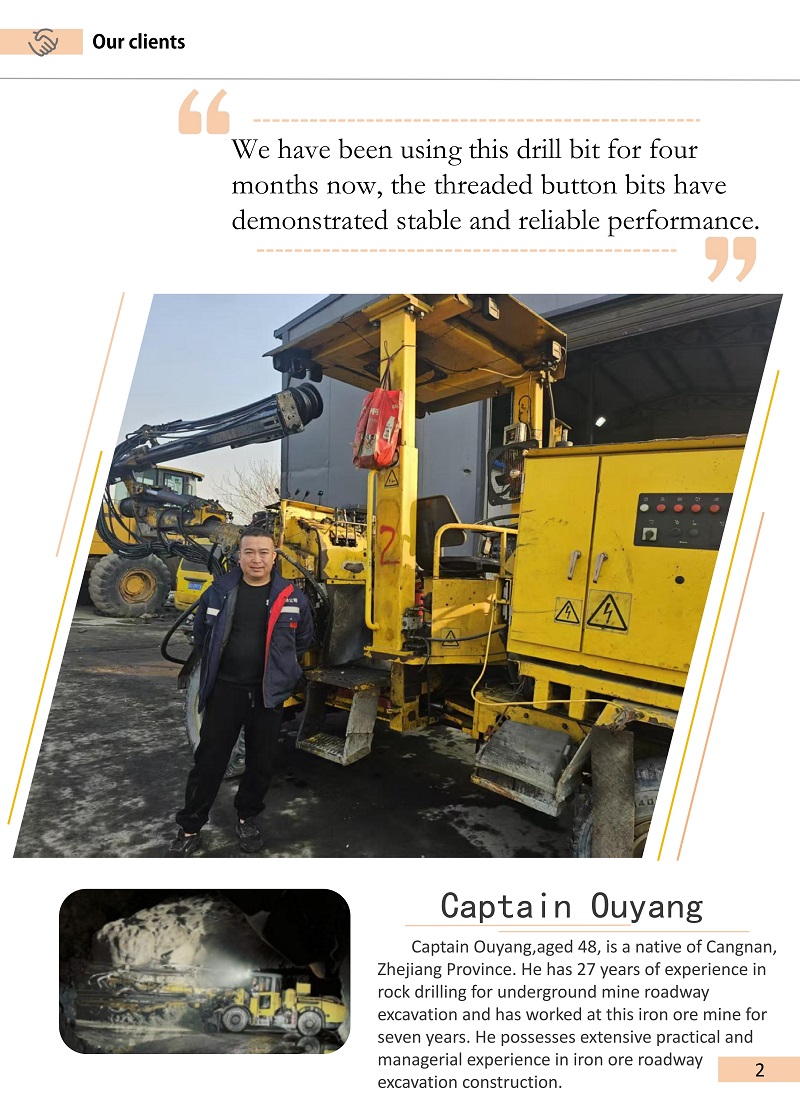

Striving for Excellence: 43R32 Drill Bit Empowers High-Performance Tunnel Excavation in Iron Ore Mining

2025-12-17

This iron ore mining project operates in a high-hardness rock environment, with rock formations characterized by biotite leptynite and plagioclase amphibolite, and a rock hardness coefficient of F = 14–16.

Key equipment:

EPIROC K111 drilling jumbo with COP1838HD+ hydraulic rock drill

Professional-grade drilling tools with T38 system, including 4300 mm drill rods and 43R32 drill bits

Results:After switching to the 43R32 drill bit, the effective drilling depth per blast hole has increased by approximately 150–200 mm, resulting in improved drilling productivity.Each rock drilling rig can complete blasting hole construction for two excavation faces per day. Each face requires 65 blast holes, taking approximately 3 hours. On average, 2–3 pcs 43R32 drill bits are needed per excavation face, fully meeting the construction requirements.

Related News